Young's Modulus Apparatus (Searle's Pattern) Manufacturer,Supplier and Exporter in India

Product Code : EL-AP-11118

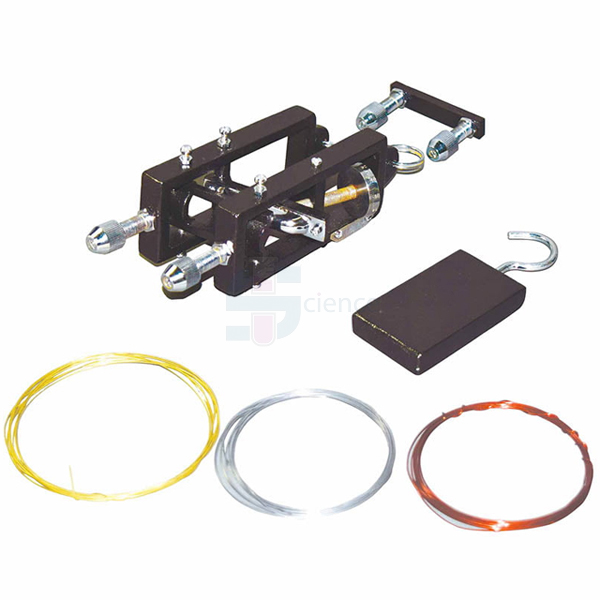

The Searle’s Pattern Apparatus is

an OEM-calibrated instrument designed for the empirical determination of

Young’s Modulus via differential longitudinal strain measurement. Engineered

for University-level engineering physics and TVET technical curricula, it

utilizes a twin-frame differential system to eliminate thermal expansion

errors, ensuring compliance with ISO and ASTM-aligned laboratory protocols.

Technical Specifications

|

Tender Specification |

OEM Technical Detail |

|

Frame Material |

High-tensile Machined Brass Frames (Twin-System) |

|

Measurement Resolution |

Integrated Micrometer Head; 0.01 mm (1/100 mm) |

|

Alignment System |

Pivoted linkage with high-sensitivity bubble spirit level |

|

Clamping Mechanism |

Dual self-centering chucks for axial load consistency |

|

Included Hardware |

Ceiling bracket, constant reference weight, and test wire |

|

Correction Method |

Differential frame geometry for thermal expansion

compensation |

Key Pedagogical Outcomes

- Dual-Frame

Differential Design: Allows students to isolate longitudinal strain

from thermal expansion or support-bracket deflection, facilitating

high-accuracy data in Thermodynamics and Mechanics modules.

- 0.01

mm Micrometer Sensitivity: Enables the detection of infinitesimal

elastic deformations, supporting Bloom’s Taxonomy levels of Analysis and

Evaluation during stress-strain curve plotting.

- Self-Centering

Chucks: Ensures perfectly axial loading to prevent shear force

interference, allowing for the rigorous calculation of the Area Moment of

Inertia and Young's Modulus ($Y$).

- Pivoted

Spirit Level Linkage: Provides a visual null-point indicator for

precision leveling, reinforcing the importance of experimental equilibrium

and systematic error reduction.

International Logistics & Compliance

Science Lab Export implements standardized protocols

for international institutional supply. All apparatus is secured in

export-grade seaworthy crating to prevent transit-related misalignment of the

micrometer assembly. Each shipment is accompanied by a Manufacturer’s

Authorization Form (MAF), IQ/OQ/PQ certification protocols, and comprehensive

technical manuals in English. The instrument features a tropicalized finish,

with brass and steel components tested for structural integrity in environments

up to 45°C and 90% non-condensing humidity.