Lift Pump Manufacturer,Supplier and Exporter in India

Product Code : EL-M-11013

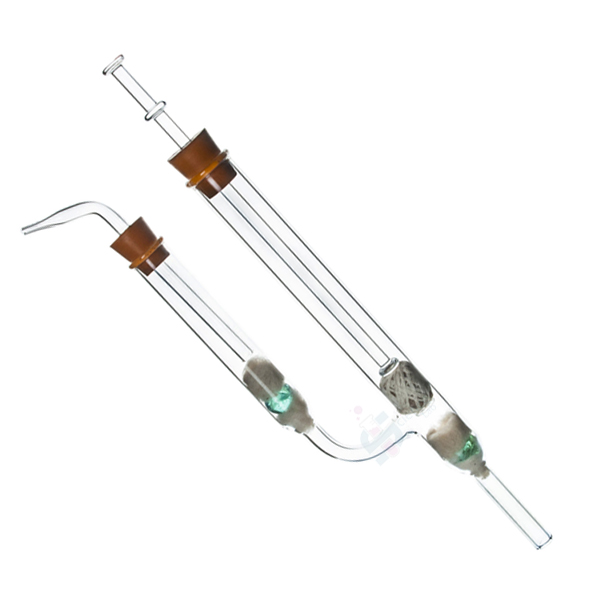

This glass Lift Pump working model facilitates the empirical

demonstration of atmospheric pressure and reciprocating suction mechanics.

Engineered for Secondary and Vocational physics curricula, it utilizes

non-return float valves to visualize fluid displacement. The unit adheres to manufacturing

standards, providing a high-integrity platform for analyzing mechanical lifting

cycles in institutional laboratory environments.

Technical Specifications

|

Tender Specification |

OEM Technical Detail |

|

Material Grade |

Chemical-resistant Borosilicate 3.3 Glass |

|

Valve Mechanism |

Precision-engineered non-return float valves |

|

Piston Configuration |

Calibrated manual reciprocating piston with airtight seal |

|

Discharge Interface |

Integrated lateral side tube for fluid outlet |

|

Chassis Stability |

Mounted on a heavy-duty, chemically-inert support base |

Key Pedagogical Outcomes

- Transparent

Borosilicate Cylinder: Allows students to analyze the

sequential operation of valves during the upstroke and downstroke,

supporting Fluid Mechanics Module 101.

- Non-return

Float Valves: Enables learners to evaluate the role of pressure

differentials in unidirectional fluid flow, facilitating practical

understanding of atmospheric force.

- Reciprocating

Piston Design: Facilitates the application of mechanical work

principles as students visualize the conversion of manual input into

hydraulic lift.

- Side

Outlet Tube: Supports the demonstration of continuous flow

cycles and volumetric displacement in suction-based systems.

International Logistics & Compliance

Science Lab Export ensures this instrument meets the

rigorous demands of international procurement officers. Packaging utilizes

export-grade seaworthy crating with shock-absorbent internal molding to protect

the glass assembly during transit. Documentation includes a Manufacturer’s

Authorization Form (MAF), IQ/OQ/PQ Certification, and comprehensive Technical

Manuals in English. The tropicalized design is tested for operational integrity

and seal durability in environments reaching 45°C and 90% non-condensing

humidity.