Jaeger's Surface Tension Apparatus Manufacturer,Supplier and Exporter in India

Product Code : EL-AP-11109

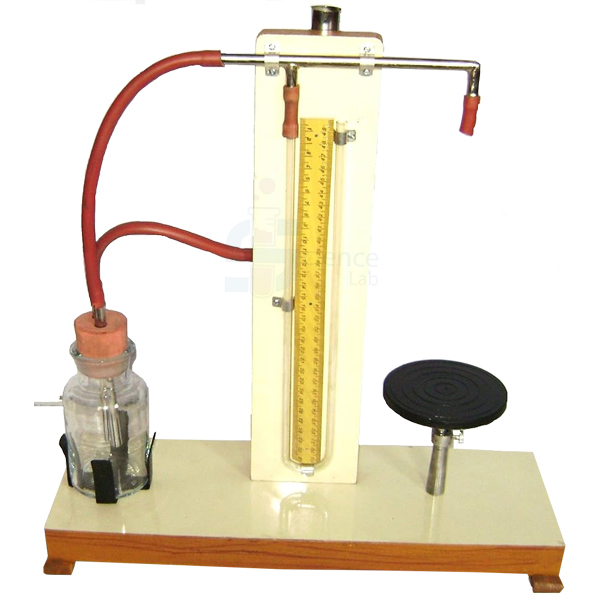

The Jaeger’s Surface Tension Apparatus is a precision

laboratory instrument engineered for the determination of liquid surface

tension via the maximum bubble pressure method. Designed for University and

Vocational physics curricula, this system facilitates high-resolution

manometric readings. It adheres to ISO manufacturing standards and is optimized

for characterizing the thermophysical properties of fluids in advanced

mechanics modules.

Technical Specifications

|

Tender Specification |

OEM Technical Detail |

|

Material Grade (Glassware) |

Low-expansion Borosilicate Glass |

|

Primary Vessel |

Wide-mouth reagent bottle with precision-ground neck |

|

Sealing System |

Dual-bore chemical-resistant cork assembly |

|

Pressure Control |

Integrated precision dropping funnel for regulated airflow |

|

Measurement System |

U-tube glass manometer mounted on graduated scale |

|

Capillary Interface |

Fine-bore vertical capillary tube for bubble formation |

|

Chassis/Stand |

Seasoned hardwood or chemical-resistant polymer-coated

wooden stand |

Key Pedagogical Outcomes

- Precision

Dropping Funnel: Enables the user to regulate the rate of bubble

formation, ensuring the system reaches quasi-static equilibrium for

accurate pressure differential measurement.

- Integrated

U-Tube Manometer: Allows students to quantify the internal pressure of

bubbles, supporting the application of the Young-Laplace equation in fluid

mechanics.

- Fine-Bore

Capillary Tube: Facilitates the study of the relationship between

capillary diameter and surface force, supporting Bloom’s Taxonomy levels

of Analysis and Synthesis.

- Open-System

Architecture (Aspirator Compatible): Encourages the integration of

auxiliary vacuum/pressure sources, allowing for experimental expansion

into variable pressure gradients.

International Logistics & Compliance

Science Lab Export manages the supply chain requirements for

international procurement agencies and educational ministries. All units are

packaged in export-grade seaworthy crating featuring high-density foam inserts

to prevent glassware fracture during transit. Full documentation, including the

Manufacturer’s Authorization Form (MAF), ISO Certificate of Conformity, and

IQ/OQ protocols, is provided. The apparatus is tropicalized for operational

stability in environments reaching 45°C and 90% humidity, ensuring long-term

resilience in diverse geographic regions.